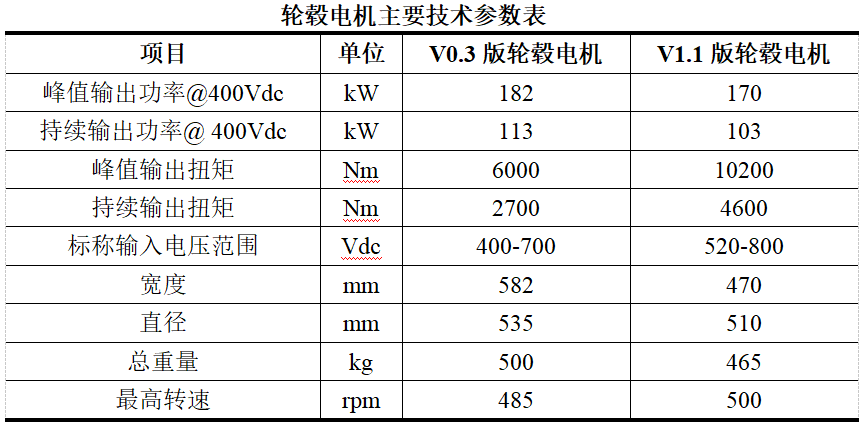

In-wheel motor

The transmission efficiency of this product can reach 94%

Compared with the 84% of the central motor drive, it is greatly improved

At the same time, the cost is reduced by 15%

The transmission efficiency of this product can reach 94%

Compared with the 84% of the central motor drive, it is greatly improved

At the same time, the cost is reduced by 15%

The hub motor used in this project is an outer rotor motor, the integrated inverter is placed inside the stator, and other hub motors are placed outside the motor. Easy to assemble, easy to maintain and easy to use due to the use of integrated electronic components and applied modularity; requires only two HVDC lines, fluid cooled inlet and outlet and one fieldbus connection and the number of fieldbus connections is kept at Minimal level; Electromagnetic compatibility issues are minimized, and the axle height is low, making it easy to use for low-floor bus applications. The transmission efficiency of this product can reach 94%, which is greatly improved compared to the 84% driven by the central motor, and the cost is reduced by 15%.

轮毂电机总成 爆炸图 逆变器

To ensure control of the powertrain, in-vehicle grid and auxiliary systems, a central controller is the main controller, applying multiple inputs such as electronic brakes, steering sensors, accelerometers, battery manager and external or internal chargers - TheControl Contains advanced functions (such as ABS and ASR) two subsystems: PCM (Powertrain Control Module) and VEM (Vehicle Energy Manager) allow to simplify the rear axle of the vehicle to simulate differential through TheControl without the need for a differential.